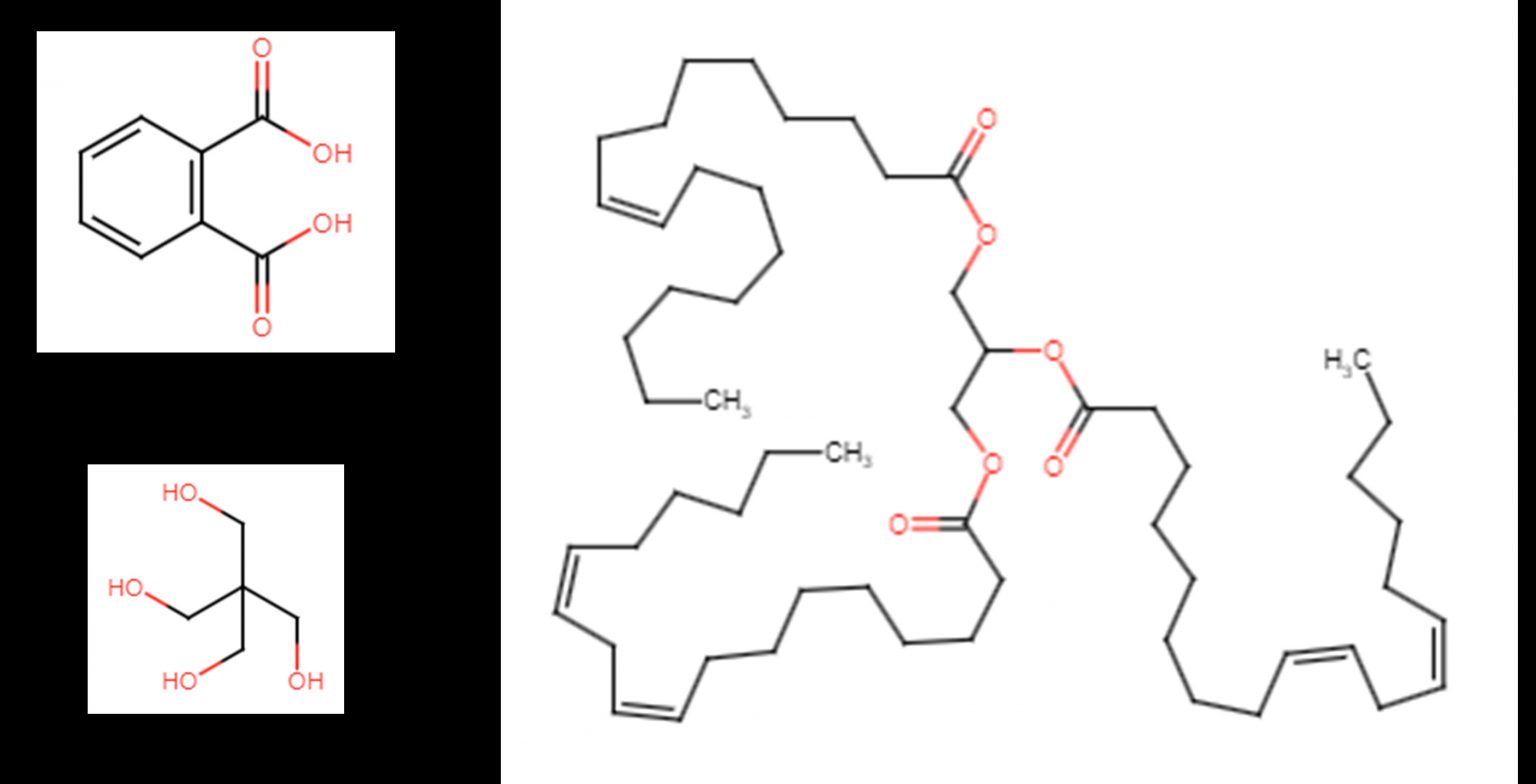

Bio-based Ingredients for Epoxy Coatings

Epoxy coatings are highly durable, corrosion resistant, and are commonly used as floor and metal coatings or as protective primers. They are typically 2-part coating systems and consist of an epoxy resin combined with a reactive hardener (such as amines, phenols, anhydrides or thiols). Traditional epoxy resin molecules are based on a rather rigid chemical structure, which, combined with high levels of crosslinking from the hardener, gives good mechanical properties to the final coating. The rigidity can however be a disadvantage, as high levels of crosslinking can make the coating brittle and inflexible. They are also sensitive to UV light, which causes cracking and flaking, hence they are only used in indoor applications, or as primers which are protected by a UV-resistant topcoat.